In the process of custom orthotic insole production and foot fitting optimization, the precise fit and corrective effectiveness of the insole both rely on scientific plantar data support.

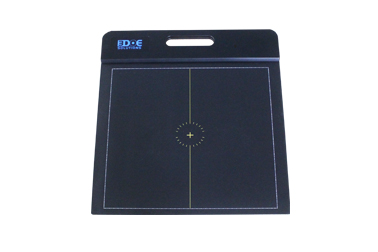

And plantar 3D laser scanning is the core enabling method to ensure the "precise fit to the sole" of the custom orthotic insole.

Under normal circumstances, this scanning technology is a "static data collection system" composed of laser ranging, contour capture, and 3D modeling.

This gives it extremely high accuracy, helping us restore the plantar shape, extract core 3D parameters, and at the same time provide a scientific basis for insole correction design.

However, its application significance is not merely data collection, nor does it involve the capture of pressure and gait-related parameters.

This technology focuses on static measurement and operates based on laser principles. Only through standardized operations can it accurately present key information about plantar fitting.

If the scanning operation is not standardized, whether it is positioning deviation or incomplete laser capture, it will directly lead to data distortion and abnormalities in insole fitting and correction effects.

And this data distortion problem will trigger a series of associated problems in insole correction effectiveness and user experience:

Inaccurate scanning data leading to unbalanced insole fitting is like knocking over a row of dominoes, which will have a chain impact on foot correction and comfort experience.

If you want to customize a custom insole with strong adaptability and good correction effect, then using plantar 3D laser scanning combined with professional correction design is a relatively good solution.

The scanning application we are talking about here is a professional link that provides core 3D data support for custom orthotic insole production.

Because each person's plantar contour, arch height characteristics, and 3D parameters vary greatly, which data affect correction fitting? How to accurately collect them?

Obviously, ordinary measurement methods that are not laser-based static measurement cannot achieve such precise data support.

This means that a set of accurate scanning data is only suitable for the custom orthotic insole needs of the corresponding user.

This is also why professional institutions will give priority to conducting plantar 3D laser scanning when customizing orthotic insoles.

Plantar 3D Laser Scanning (Special Application for Custom Orthotic Insoles)

01 Through laser measurement principles, record the complete contour of your plantar when standing statically and collect core 3D parameter data.

02 Use professional analysis equipment to accurately sort out and analyze plantar 3D data and morphological characteristics.

Integrate scanning data, combine with foot correction evaluation, and conduct personalized design for insole support points and fit.

Guide cutting based on accurate data to produce a custom insole that fits the sole and has precise correction effectiveness.

Its application collects accurate static 3D plantar parameters to provide scientific support for custom orthotic insole production, thereby achieving the goals of improving fit, ensuring correction effect, and optimizing foot comfort experience.

+86-0755-86131192

+86-0755-86131192 2026-01-29

2026-01-29 Back to list

Back to list

+86-0755-86131192

+86-0755-86131192