In scenarios of foot data collection and precise shape restoration, the measurement accuracy and parameter validity of the device both depend on the support of core technology.

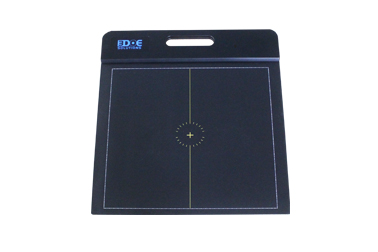

The core of the laser plantar scanner is the reliance on “laser technology” to achieve precise capture of three-dimensional plantar information.

Under normal circumstances, its working core consists of a “static measurement structure” composed of a laser emission module, a contour receiving module, and a data modeling module.

This gives it extremely high accuracy, helping us capture plantar contours, extract three-dimensional parameters, while also ensuring data integrity and reliability.

However, its working principle does not involve dynamic detection, nor does it include the collection of parameters related to pressure or gait.

When the device operates, static measurement is the core, and it requires a stable standing posture. Data acquisition is completed through the precise projection and reception of the laser.

If the operating scenario is not standardized, whether due to posture sway or laser obstruction, it will directly cause data deviation and abnormal parameter restoration.

This deviation in data can trigger a series of problems in subsequent applications and analyses:

Inaccurate scan data leads to distorted parameter restoration, like toppling a row of dominoes, bringing a chain effect to subsequent adaptation and evaluation.

If you want to clearly understand the device’s working logic and ensure the accuracy of scan data, then mastering its core principle and following standardized operation is a good approach.

The working principle we are referring to here is the core logic by which the laser plantar scanner achieves static three-dimensional measurement.

Because measurement requirements vary across different scenarios, and plantar shapes differ between individuals, which part actually ensures accuracy? How should operation be standardized?

Clearly, ordinary measurement devices that do not rely on laser principles cannot achieve such precise static capture.

This is also why professional institutions strictly standardize operational procedures when using laser plantar scanners.

Core working process of the laser plantar scanner

01 Through laser emission technology, precisely project laser beams onto the statically standing plantar to capture contour point information.

02 Use the receiving sensor module to analyze the laser signals reflected from the plantar and convert them into basic coordinate data.

Integrate the coordinate data, and combine it with three-dimensional modeling algorithms to accurately restore parameters of the plantar shape.

Generate a complete three-dimensional plantar data report, providing accurate data support for subsequent applications.

The laser plantar scanner, through laser projection and signal analysis, achieves static three-dimensional parameter acquisition of the plantar, thereby restoring plantar shape, ensuring data accuracy, and supporting professional applications.

+86-0755-86131192

+86-0755-86131192 2026-01-29

2026-01-29 Back to list

Back to list

+86-0755-86131192

+86-0755-86131192