In today's rapidly advancing technological world, 3D printing is permeating various aspects of our lives at an astonishing pace. From high-end manufacturing to everyday consumer products, its unique charm is evident everywhere.

In the field of healthcare, the application of 3D printing has opened a new era of personalized treatment.

This article will delve into how 3D printing technology helps customize perfect orthotic insoles, effectively improving foot health and making every step more stable and comfortable.

I. Limitations of Traditional Orthotic Insoles

Traditional orthotic insoles are often made using manual measurements and standardized molds. While this approach can meet the needs of some individuals to a certain extent, it is limited by measurement precision, material selection, and the lack of personalized design, often failing to achieve the optimal corrective effect.

This is especially true for patients with complex foot structures or special needs, as traditional insoles may not fit properly, or even exacerbate foot problems due to discomfort.

II. The Intervention of 3D Printing Technology: A New Chapter in Precision Customization

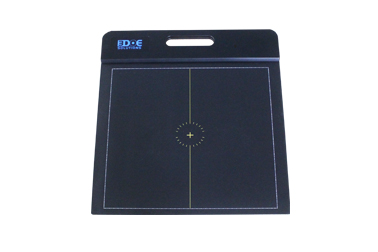

The advent of 3D printing technology has brought a revolutionary breakthrough in the personalized customization of orthotic insoles. Through high-precision 3D scanning technology, the patient's foot data can be quickly obtained and input into 3D design software to create an accurate model.

Designers can create one-on-one customized designs based on the patient's specific condition, such as arch height, foot pressure distribution, gait characteristics, etc., ensuring that every part of the insole perfectly fits the patient's foot shape.

III. The Role of Material Science: The Perfect Combination of Comfort and Function

3D printing not only enables personalized design but also offers limitless possibilities in material selection.

Modern 3D printing technology can use a variety of high-performance materials, such as elastic TPU, nylon composites, etc. These materials are not only lightweight and durable but also have excellent elasticity and support. The hardness and softness can be adjusted according to the patient's needs to achieve the best combination of comfort and corrective effect.

Additionally, some advanced 3D printing materials have breathable, antimicrobial, and other properties, further enhancing the wearing experience of the insoles.

IV. From Design to Finished Product: An Efficient and Rapid Production Process

Compared to traditional manufacturing methods, the production process for 3D printed orthotic insoles is more efficient and faster. Once the design is complete, the 3D printer can layer by layer stack the material to quickly produce the insole.

This process significantly shortens production time, allowing patients to receive their customized orthotic insoles more quickly. Moreover, the precision of 3D printing ensures that every pair of insoles meets medical-grade quality standards, providing strong assurance for foot health.

V. Case Studies: Real-World Success Stories

Many patients have experienced significant improvements through 3D printed orthotic insoles. For example, a runner who had been suffering from plantar fasciitis for a long time found relief after using 3D printed custom insoles, not only alleviating pain but also improving running efficiency.

Another case involves a child with flat feet, whose arch shape improved noticeably after wearing 3D printed orthotic insoles for some time, leading to a more natural walking posture. These successful cases fully demonstrate the tremendous potential of 3D printed orthotic insoles in improving foot health.

As 3D printing technology continues to mature and costs continue to decrease, 3D printed orthotic insoles are expected to become a healthier choice for more people.

They not only provide a more precise and effective treatment solution for patients with foot diseases but also offer the potential for healthy individuals to prevent foot problems and improve their quality of life.

We have every reason to believe that, in the near future, 3D printing technology will have a broader and more profound impact on the healthcare field, allowing everyone to step forward into the future with healthier and more confident feet.

+86-0755-86131192

+86-0755-86131192 2024-11-13

2024-11-13 Back to list

Back to list

+86-0755-86131192

+86-0755-86131192