Although China is the largest shoe-making country, it is still far from the shoe-making power. The shoe-making technology is backward, the advanced manufacturing concept, and the technology is rarely traced in the shoe-making enterprises. The technological strength is obviously insufficient, and the shoe-making process is still on a large scale. Industrial production is the main mode of production. The production flexibility brought by mechanized mass production is poor, the speed of product replacement is slow, and the disadvantages of not being able to meet the individual needs of each customer are also obvious. In China's shoe industry, there is an urgent need for quantity-oriented In the historical situation of the transition to quality and efficiency, the advanced concept represented by agility and the advanced manufacturing technology represented by intelligent manufacturing will be the main means for the footwear industry to quickly respond to market demand, win competition and seek development.

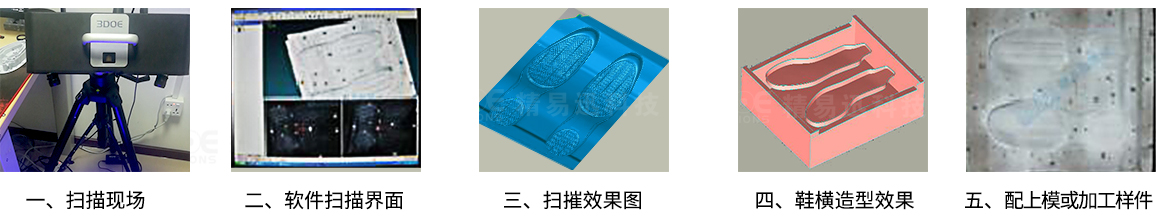

The following uses the Jingyixun blue light camera 3D scanner to quickly scan shoe molds, shoe soles, etc., to obtain high-density three-dimensional scan data and model data.

Customer demand:

1. Hope to get the bottom modulus data of the sole mold quickly

2. Accurately extract the parting line of sole

3. Improve efficiency and reduce labor

4. Current difficulties that customers need to solve:

Traditional shoemaking technology is more and more difficult to adapt to the needs of the rapid development of modern shoemaking industry; Can not meet the customer's personalized customized services.

Sole mold 3D scanning solution (Blu-ray camera 3D scanner)

1. Preparation

First, surface treatment of the scanned sample:

1) Since the 3D scanner uses an optical method to scan the object, because the surface of the object is a reflective object, it needs to be surface treated and sprayed with a developer

2) Paste the marked points, and the splicing of marked points is executed by software algorithm. The three-dimensional scanning system needs to superimpose the common mark points identified between the two images so that the two scans exist in a unified coordinate system, so as to achieve complete data splicing

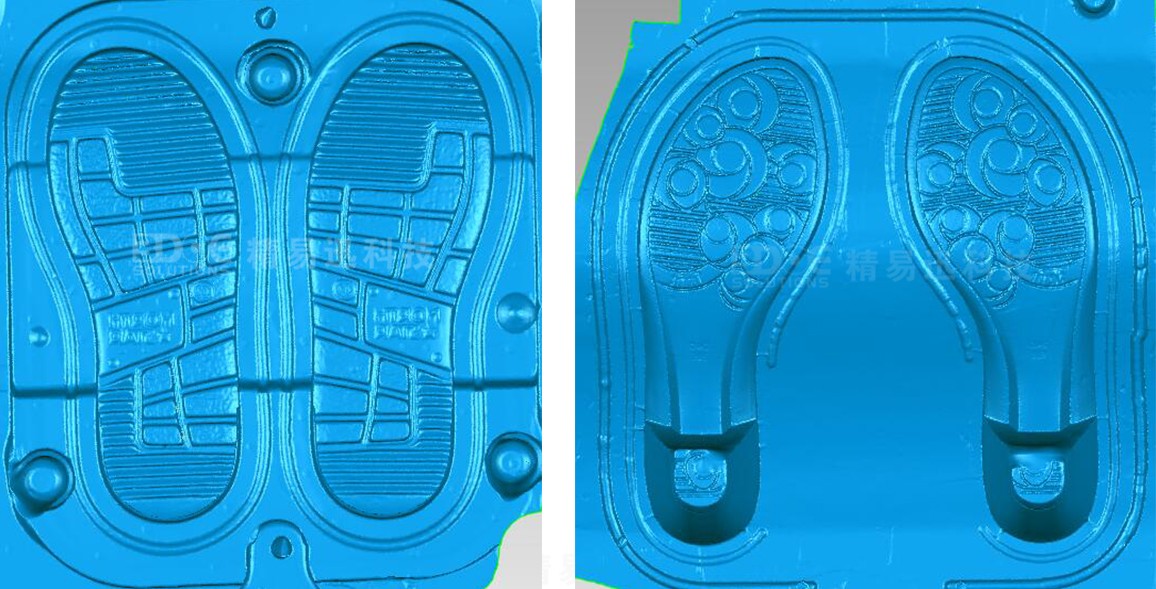

2. Scan to obtain 3D data

The sole mold is scanned in 3D, and our technical engineers use a blue-light camera-type 3D scanner (PTS-E) to scan to quickly obtain the 3D data of the sole mold.

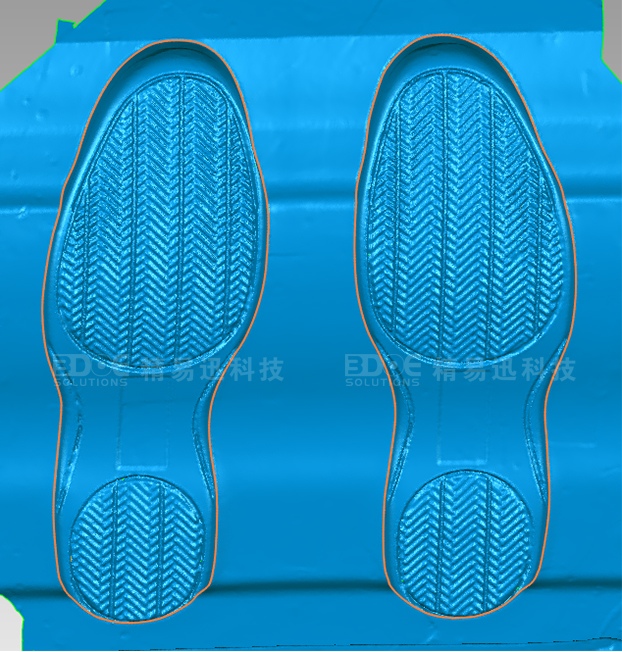

3. Extract the parting line from the 3D data of the sole mold

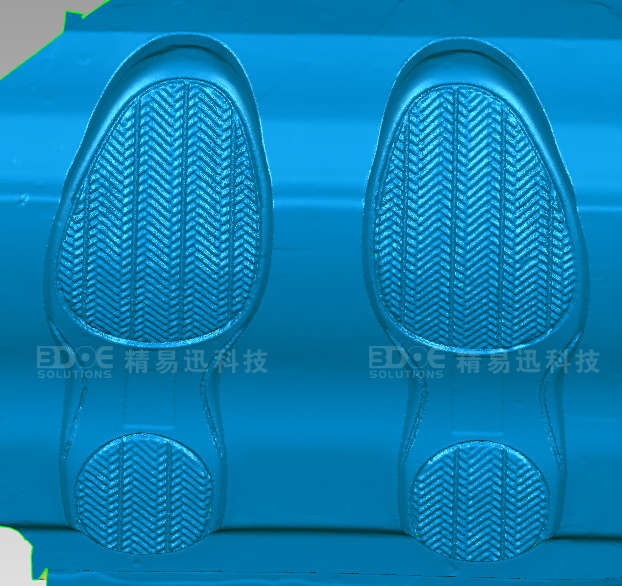

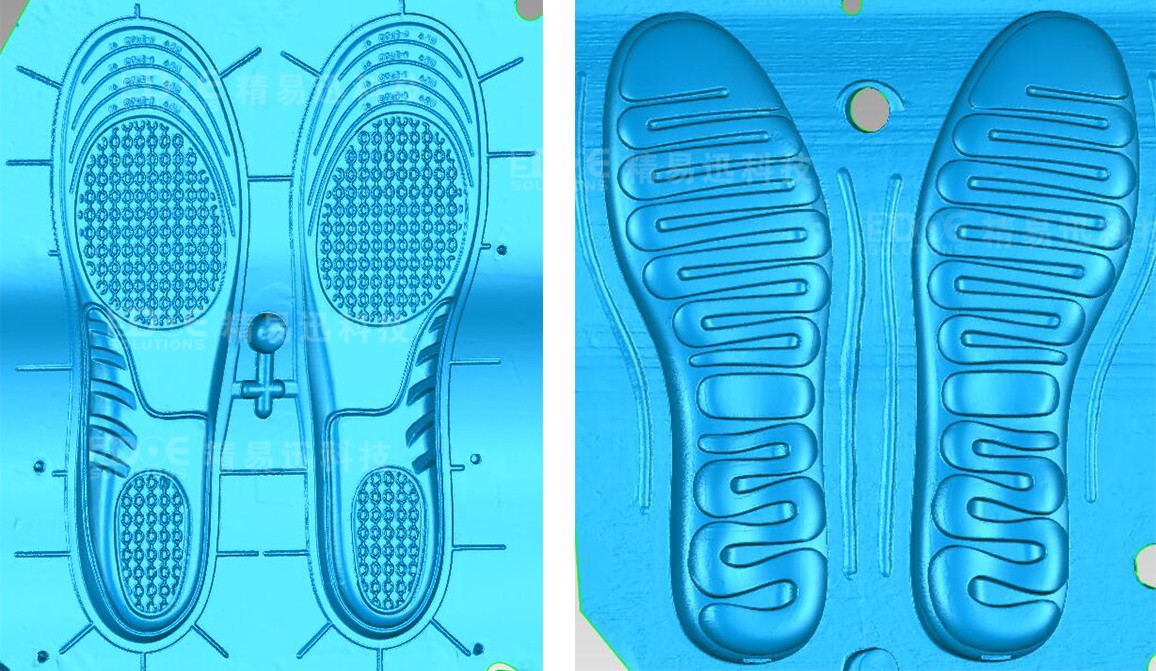

The 3D scanner scans the sole model and displays it as follows:

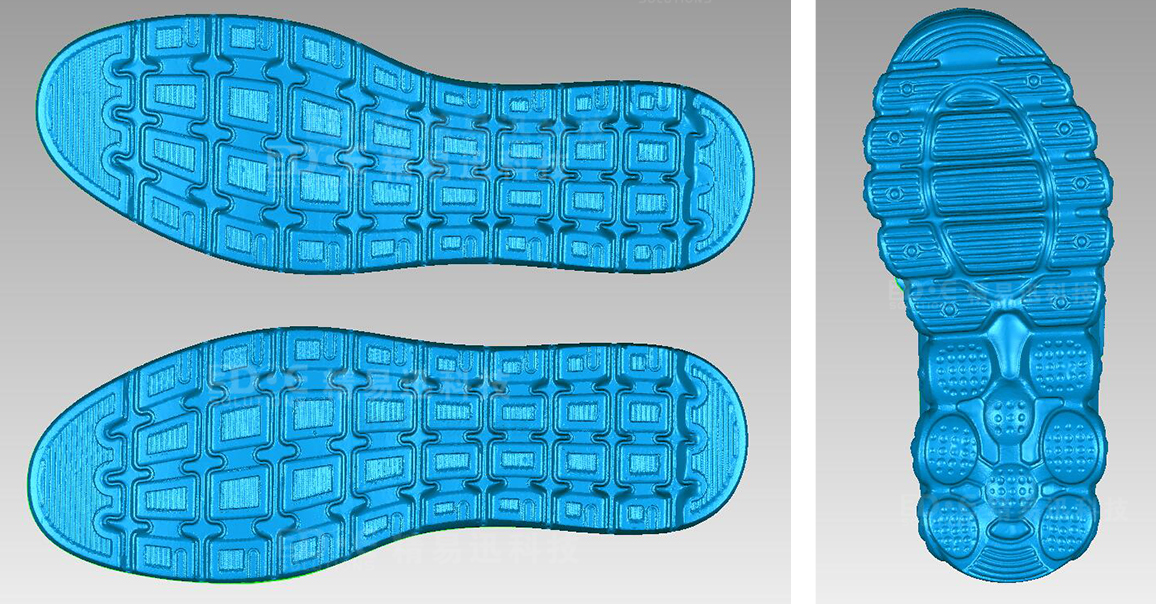

The shoe sole scanned by the 3D scanner is shown as follows:

Highlights of the blue-light camera-type 3D scanner used in the 3D scanning solution of the sole mold

1. Using blue light non-contact scanning

2. Multi-angle scanning, automatic stitching, can avoid dead ends as much as possible

3. The scanned 3D data can be extracted using geomagic software to extract parting lines

4. Can quickly obtain sole mold data

Summary of 3D digital solutions for sole molds:

Jingyixun's Blu-ray Photographic 3D Scanner scans shoe sole molds, which can quickly obtain 3D data, and can increase individual requirements for enterprises in the production process, achieve significant benefits in terms of work efficiency and work quality, improve product manufacturing capabilities, and shorten products Manufacturing cycle, reduce manufacturing costs, improve the market competitiveness of products, and can quickly reduce labor costs for customers, and can continue to add value in the shoe industry, as soon as possible to adapt to the development of the modern shoe industry.

+86-0755-86131192

+86-0755-86131192

+86-0755-86131192

+86-0755-86131192