Flat feet, high arches, foot eversion, inward-pointing gait, unstable walking, recurrent knee pain… These problems often affect the mechanical stability of the lower limbs. Without scientific evaluation, correction is often inefficient.

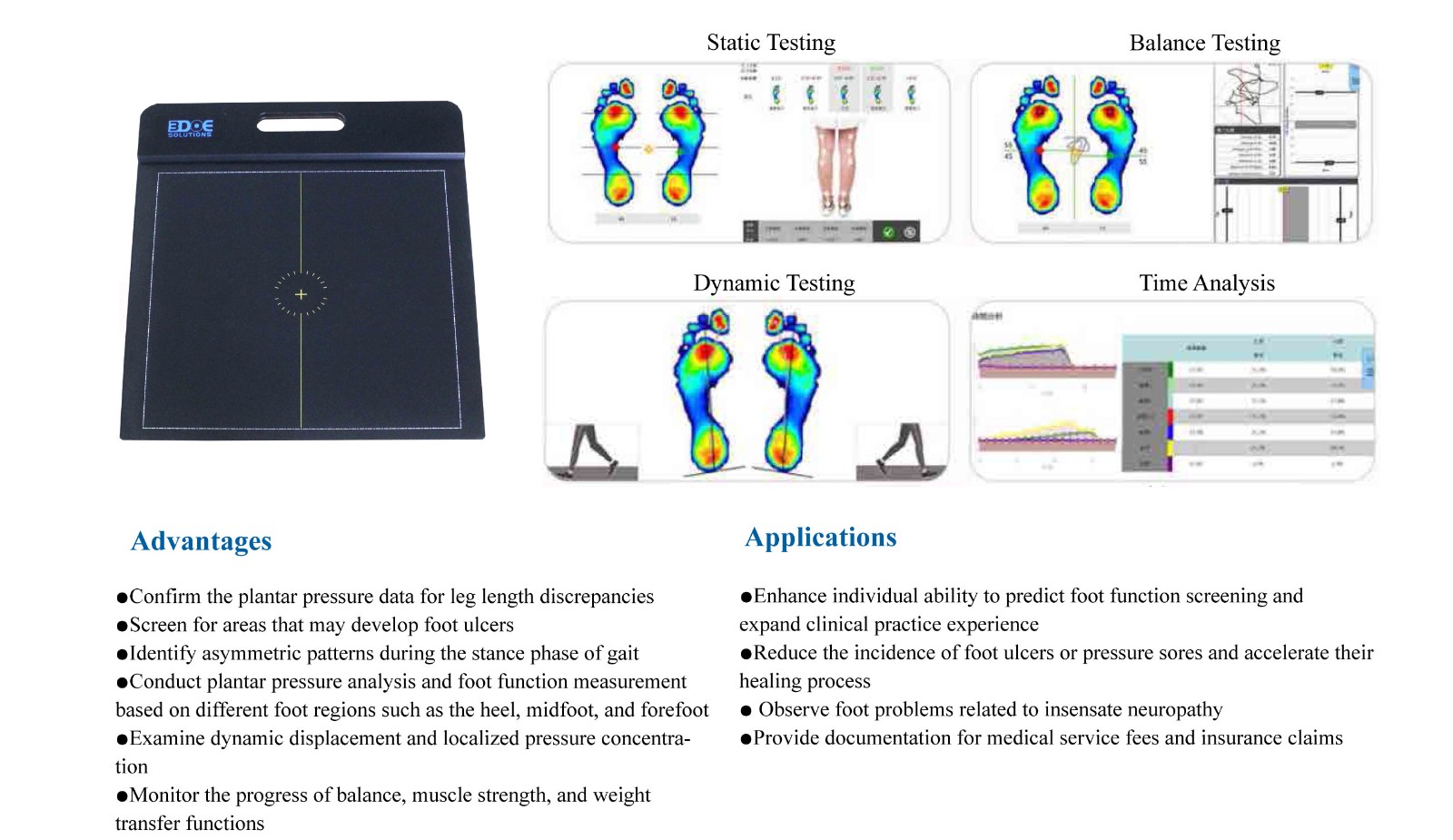

Just as an optometer can accurately detect vision status, a plantar pressure gait evaluation system can also record the distribution of plantar pressure and changes in gait during standing, walking, and running, providing accurate data support for the design of professional corrective insoles.

Corrective insoles must not only have reasonable design but also be based on scientific testing. So, what are the important advantages of custom orthotic insoles made using a plantar pressure gait evaluation system to measure foot pressure?

I. In line with biomechanical analysis principles

1. Accurate pressure collection

The plantar pressure evaluation system can monitor the forces on different areas of the foot in real time during standing and walking, such as heel impact force, arch support force, and forefoot push-off pressure.

For flat-footed individuals, it is possible to clearly observe excessive medial pressure caused by arch collapse; for high-arched individuals, abnormal concentration of force on the forefoot and hindfoot can be displayed, thus providing more targeted support solutions for insoles.

2. Optimization of lower limb force lines

While viewing plantar data, the system can also display changes in lower limb biomechanical lines based on gait trajectories, such as landing angles, center of gravity movement paths, and differences in force between the two feet.

Through the redistribution of plantar mechanical load, insoles can guide the knee, ankle, and hip joints back to more reasonable biomechanical postures, reducing additional wear caused by misaligned force lines. Populations with O/X-shaped legs, foot eversion, and foot internal rotation can achieve significant improvement through pressure-guided insole correction.

II. Professional data supporting personalized customization

1. Individualized scientific modeling

Foot plantar pressure distribution, arch height, soft tissue support capacity, and gait patterns vary among individuals. Therefore, effective corrective insoles must start from the individual’s biomechanical characteristics. Conducting plantar pressure tests and gait analysis on the system can obtain:

Rhythm of gait

Peak pressure points

Variation pattern of arch load

Left-right force differences

Stability of center of gravity trajectory

Based on complete data modeling, insoles can truly be “made for the foot” rather than blindly templated.

2. Adapting to long-term changes in the foot

For children in skeletal development, postoperative rehabilitation patients, or people with increasing physical activity, the foot condition changes over time. The evaluation system can perform periodic re-tests and continuously record pressure changes and gait progress. Insoles can also dynamically adjust according to these changes, ensuring continuous and effective correction.

III. Highly compatible insole design and production

1. Digitized support design

Collected data can be directly imported into insole design software. Technicians can design according to plantar pressure heat maps:

Adjust arch support height

Strengthen and stabilize the heel cup depth

Design forefoot cushioning areas

Optimize the three-point support structure of the foot

Based on simulation results, insole structures can be quickly optimized, ensuring that “from concept to production” is based on quantitative models rather than experience.

2. CNC machining ensures stability

The data model can be directly applied to CNC cutting and 3D printing processes, ensuring higher dimensional accuracy and better shape consistency of insoles, without manual molding errors. Splicing, bonding, and curved surface forming processes can also be automatically optimized according to the data, so that the insoles do not delaminate or deform during long-term use.

IV. Better comfort and adaptability

1. Scientifically balanced support distribution

Insoles manufactured using pressure evaluation methods can make the bearing capacity of the shoe bottom more reasonable, avoiding overload in specific areas or suspension in certain regions, producing effects during walking such as:

Stabilized heel

Proper arch support

Smooth forefoot push-off

This not only improves the foot’s load distribution but also alleviates compensatory pain in the knees, hips, and lower back.

2. Natural fit and easy adaptation

When users wear the insoles, a new force pattern is unconsciously generated during regular walking. The system can also be used for post-fitting re-testing to verify correction effects and help the body naturally adapt to a healthier gait.

+86-0755-86131192

+86-0755-86131192 2025-11-20

2025-11-20 Back to list

Back to list

+86-0755-86131192

+86-0755-86131192