Insole Customization Equipment — The Use of 3D Foot Pressure Distribution System and 3D Printers

In today's pursuit of personalization and comfort, insole customization has become an increasingly popular choice for many people.

Traditional insole manufacturing methods often rely on manual measurements and cutting, which are not only time-consuming and labor-intensive but also difficult to ensure precision.

However, with the rapid development of technology, the emergence of the 3D Foot Pressure Distribution System and 3D printers has brought about a revolutionary change in the insole customization industry.

This article will explore the use of these two devices in insole customization and how they are jointly propelling the industry into a new era.

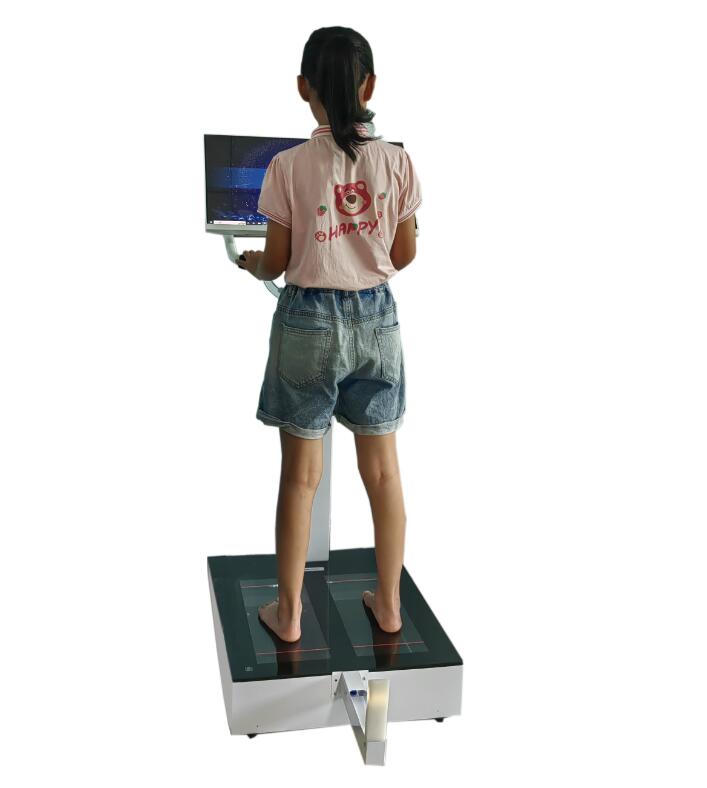

1. 3D Foot Pressure Distribution System: The Secret Weapon for Precise Measurement

The 3D Foot Pressure Distribution System is a high-tech device that uses non-contact scanning technology to quickly capture 3D shape data of the foot.

Its operating principle is similar to radar or sonar: by emitting beams or sound waves and receiving the reflected signals, it constructs a 3D model of the foot. This scanning method is not only fast but also highly accurate, capable of capturing millimeter-level detail.

In insole customization, the role of the 3D Foot Pressure Distribution System is indispensable. First, it provides users with personalized foot data.

Everyone's foot shape is unique, and through scanning, we can obtain accurate information on foot size, arch curvature, and pressure distribution. This data forms the foundation of custom insoles and is key to ensuring comfort.

Additionally, the 3D Foot Pressure Distribution System improves production efficiency.

Traditional measurement methods require manual operation, which is not only time-consuming but also prone to errors. In contrast, the scanner can complete the measurement in just a few seconds, greatly improving work efficiency. Furthermore, the data can be transferred to a computer, facilitating subsequent design and production.

2. 3D Printer: The Manufacturing Hub for Personalized Insoles

A 3D printer is a rapid prototyping device that works based on digital model files, converting 3D designs from a computer into physical objects. In the field of insole customization, the 3D printer plays a crucial role.

First, the 3D printer enables personalized customization. Based on the data obtained from the 3D Foot Pressure Distribution System, we can use 3D design software to create an insole model that matches the user's foot shape.

Next, the model file is imported into the 3D printer, which prints the insole layer by layer according to the design. This personalized manufacturing method not only meets the user's unique needs but also enhances the comfort of the insole.

Furthermore, 3D printers offer high flexibility. They can print insoles in various shapes, sizes, and materials, catering to different users' needs.

For example, for users requiring special support or cushioning, we can design insole models with specific features and use 3D printing to manufacture them.

Moreover, 3D printers reduce production costs. Traditional insole manufacturing methods require molds and extensive manual labor, whereas 3D printers can directly print from a digital model without the need for molds or complex manual operations.

This not only reduces production costs but also shortens production cycles.

3. The Future Outlook for the Insole Customization Industry

With the continuous development and widespread adoption of the 3D Foot Pressure Distribution System and 3D printers, the insole customization industry is poised for broader growth.

First, personalized customization will become the mainstream trend. Users will be able to customize insoles based on their needs and preferences, achieving a more comfortable and tailored wearing experience.

Secondly, smart manufacturing will become a reality. By integrating the 3D Foot Pressure Distribution System and 3D printers into an intelligent system, we can automate the production of insoles and seamlessly connect the process with personalized customization.

This will significantly improve production efficiency, reduce costs, and accelerate the growth of the insole customization industry.

The use of the 3D Foot Pressure Distribution System and 3D printers has brought about a revolutionary change in the insole customization industry. These technologies not only improve the precision of measurements and production efficiency but also enable personalized customization and intelligent manufacturing.

+86-0755-86131192

+86-0755-86131192 2024-11-14

2024-11-14 Back to list

Back to list

+86-0755-86131192

+86-0755-86131192