Position:Home > Products > 3D Handheld Scanner > Laser handheld 3D scanner > eSharp P7 Handheld 3D Scanner (Red Light)

+ Plantar Pressure Measurement System

Tel:+86-0755-86131192

Email:info@3doe.com

Address:6th floor, Minzhi chamber of Commerce building, Minzhi Avenue, Longhua District, Shenzhen

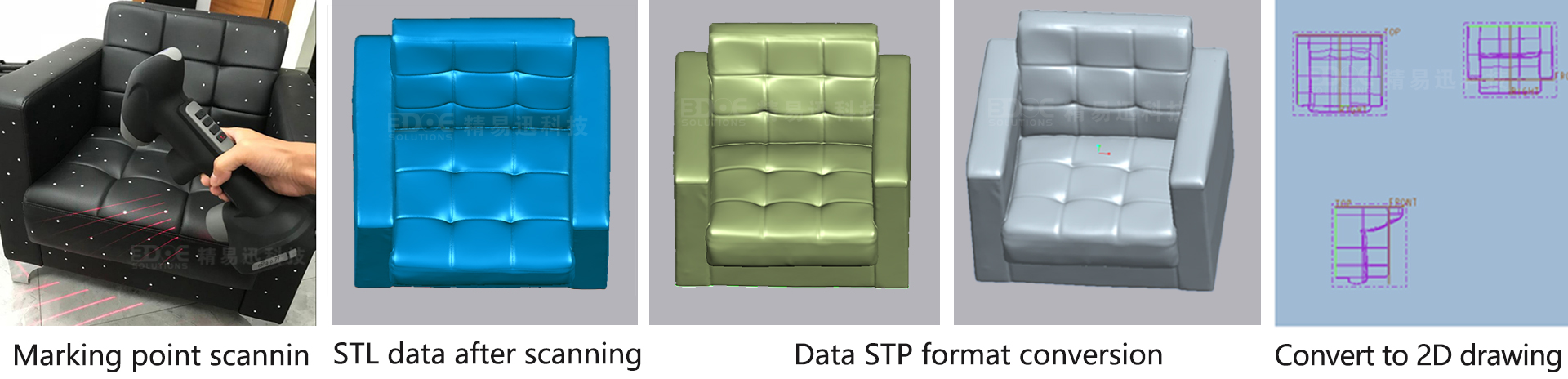

The eSharp P7 handheld laser 3D scanner uses a red laser light source and 14+1 scanning laser lines, which can quickly obtain 3D data on the surface of an object, and can scan black and bright objects with high accuracy and efficiency with high compatibility. It has a wide range of applications, such as quality 3D detection and control, reverse design, 3D digital display, medical and health, 3D printing, education and scientific research. The operation is simple and flexible, suitable for various complex application scenarios.

The eSharp P7 handheld laser 3D scanner uses 14+1 red scanning laser lines, which can quickly obtain 3D data on the surface of an object, and with high compatibility, it can scan black and bright objects with high precision and efficiency. It has a wide range of applications, such as quality 3D detection and control, reverse design, 3D digital display, medical and health, 3D printing, education and scientific research. The operation is simple and flexible, suitable for various complex application scenarios.

Features

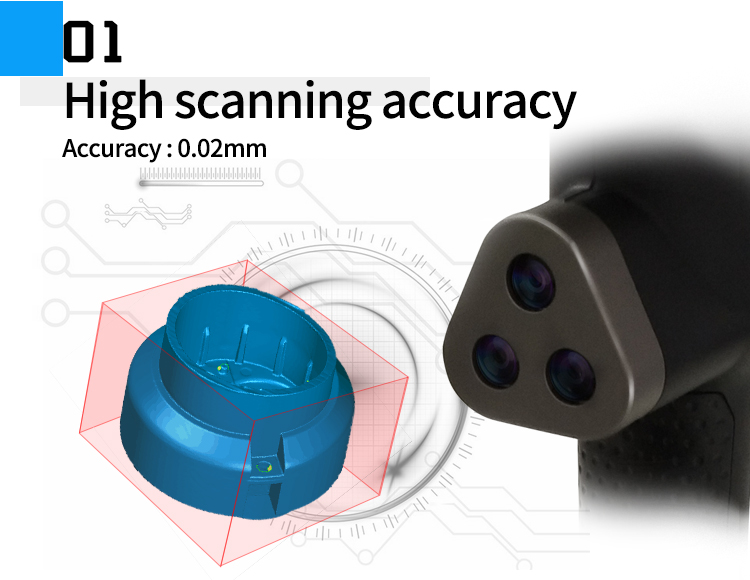

1. Industrial grade accuracy: volume accuracy up to 0.02+0.06mm/m

2. Simple operation (visual operation): The equipment is simple to operate, easy to learn and use, real-time visualization, and users can see the situation and corresponding location of the scanned workpiece through the computer.

3. Fast scanning speed: 14 scanning laser lines + 1 fine scanning laser line, scanning speed up to 480,000 measurements/sec, using an efficient and stable USB3.0 interface to achieve a very high rate of data transmission

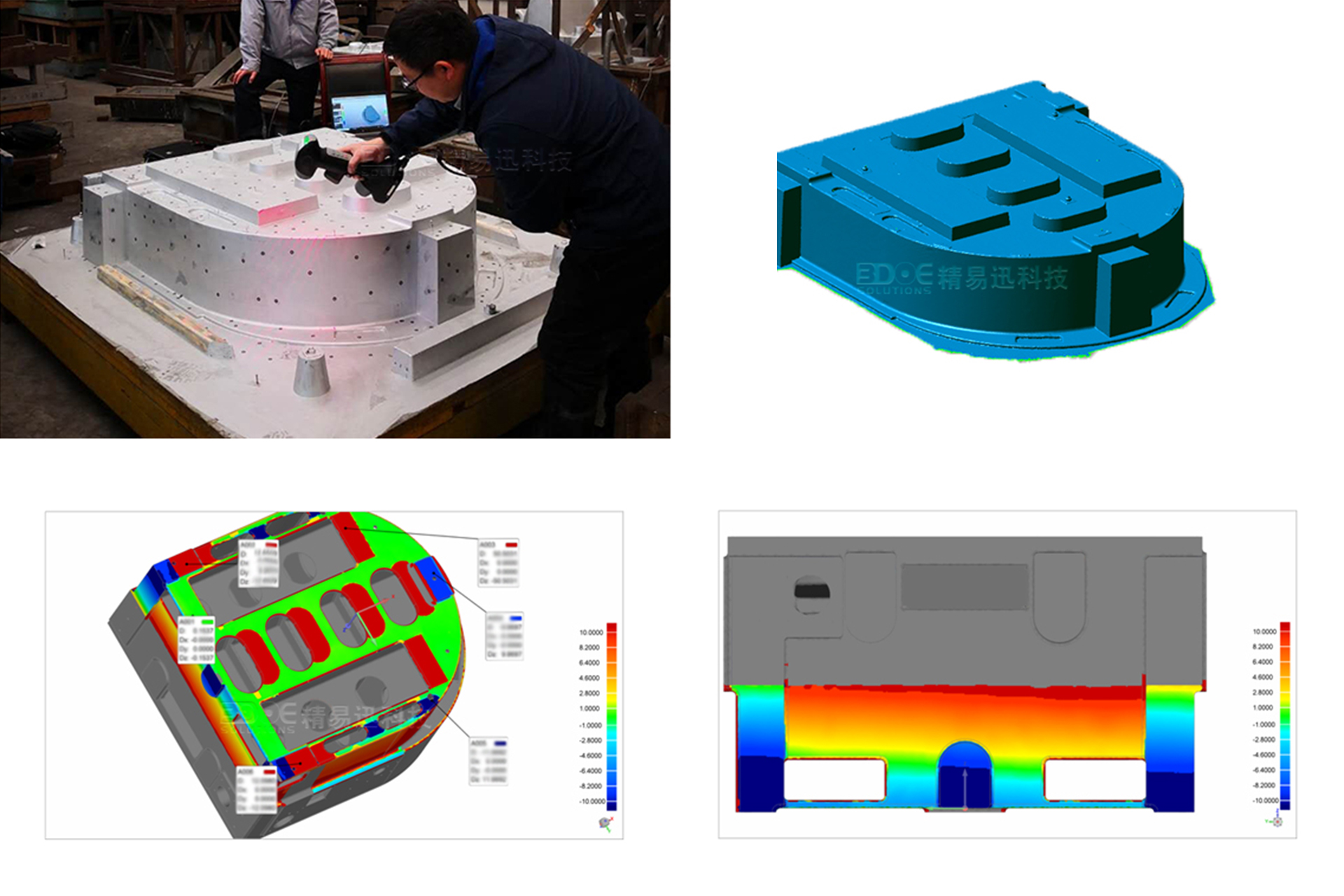

▣ Classic cases

Three-dimensional scanning inspection of large castings

▣ Technical Parameters

Product Model | eSharp-P series | |

eSharp-P7 | eSharp-P3 | |

Measuring speed | 480,000 measurements/sec | 205,000 measurements/sec |

light source | Laser 14+1 beam | Laser 6+1 beam |

weight | 0.80kg | |

Size(mm) | 310×147×80 | |

Scanning area(mm) | 275x250 | |

Measuring accuracy(mm) | Up to 0.02 | |

Volume accuracy(mm/m) | 0.03+0.06 | |

Volume accuracy (mm/m) (Combined with 3D photogrammetry system) | 0.03+0.025 | |

Laser category | ClassII eye safety level | |

Resolution(mm) | Up to 0.05 | |

Depth of field(mm) | 250 (automatic) | |

Working distance(mm) | 300 | |

transfer method | USB3.0 | |

Working temperature (Celsius) | -20~40 | |

Working humidity (non-condensing) | 10~90% | |

Data output format | .stl, .obj, .asc, .ply, .txt, .xyz, etc., can be customized. | |

Compatible software | 3D Systems(Geomagic Solutions),InnovMetric Softwre(PolyWorks) Dassault Systems(CATIV V5 and SolidWorks),PTC(PRO/ENGINEER) Autodesk(inventor、Alias、3ds max、Maya、Softimage),Siemens(NX and Solid Edge) | |

▣ Application fieldIt can scan all kinds of objects of different sizes and multiple types of surface colors, and automatically complete data modeling and other applications, truly achieving multiple uses in one machine.

Automobile transportation: Mold manufacturing: Consumer products:

1. Reverse design engineering 1. Proposed assembly 1. Product modeling and design

2. Competitive product analysis 2. Reverse design engineering 2. Reverse design

3. Car modification 3. Quality control and three-dimensional inspection 3. Quality control/inspection

4. Interior and exterior decoration customization 4. Wear analysis and maintenance 4. Packaging and advertising

5. Quality control and parts measurement (three-dimensional inspection)

6. Simulation and Finite Element Analysis (FEA)

To understand the specific application, please feel free to consult online (message) or

call 0755-86131192!

Provide system customized solutions!