Position:Home > Products > 3D Handheld Scanner > Laser handheld 3D scanner > eSharp P10 Handheld 3D Scanner (Blu-ray)

+ Plantar Pressure Measurement System

Tel:+86-0755-86131192

Email:info@3doe.com

Address:6th floor, Minzhi chamber of Commerce building, Minzhi Avenue, Longhua District, Shenzhen

The handheld 3D blue laser scanner uses a blue laser light source, 14 scanning laser beams + 5 fine scanning laser beams + 1 deep hole scanning laser beam. It can scan the fine parts of small features and easily obtain 3D data on the workpiece with high-gloss surface. Industrial-grade precision, with built-in hole position flash measurement function, can extract the center point coordinates and hole diameter from the instant measurement of the workpiece hole position .

The eSharp P10 handheld 3D blue laser scanner uses a blue laser light source, 14 scanning laser beams + 5 fine scanning laser beams + 1 deep hole scanning laser beam. It can scan the fine parts of small features, and easily obtain 3D data on the workpiece with bright surface. Industrial-grade precision, with built-in hole position flash measurement function, can extract the center point coordinates and hole diameter for the instant measurement of the workpiece hole position .

Features

1. Blue laser light source: the scanning speed is faster, and the blue laser has a shorter laser wavelength, especially for high-brightness and high-reflective materials, which has a good scanning effect.

2. Dual scanning mode: standard mode and fine mode, which can realize fine scanning of small features of the workpiece.

3. Flash measurement function: the instant measurement of the workpiece hole position can extract the center point coordinate and hole diameter.

4. Visual operation: the computer will display the scan results synchronously while scanning, you can view the scan status and effect in real time, and you can scan again after saving.

5. Scanning flexibility: The device is small in size and can be operated in a narrow space. During the measurement process, the parts and the scanner can be moved freely without affecting the scanning effect of the device.

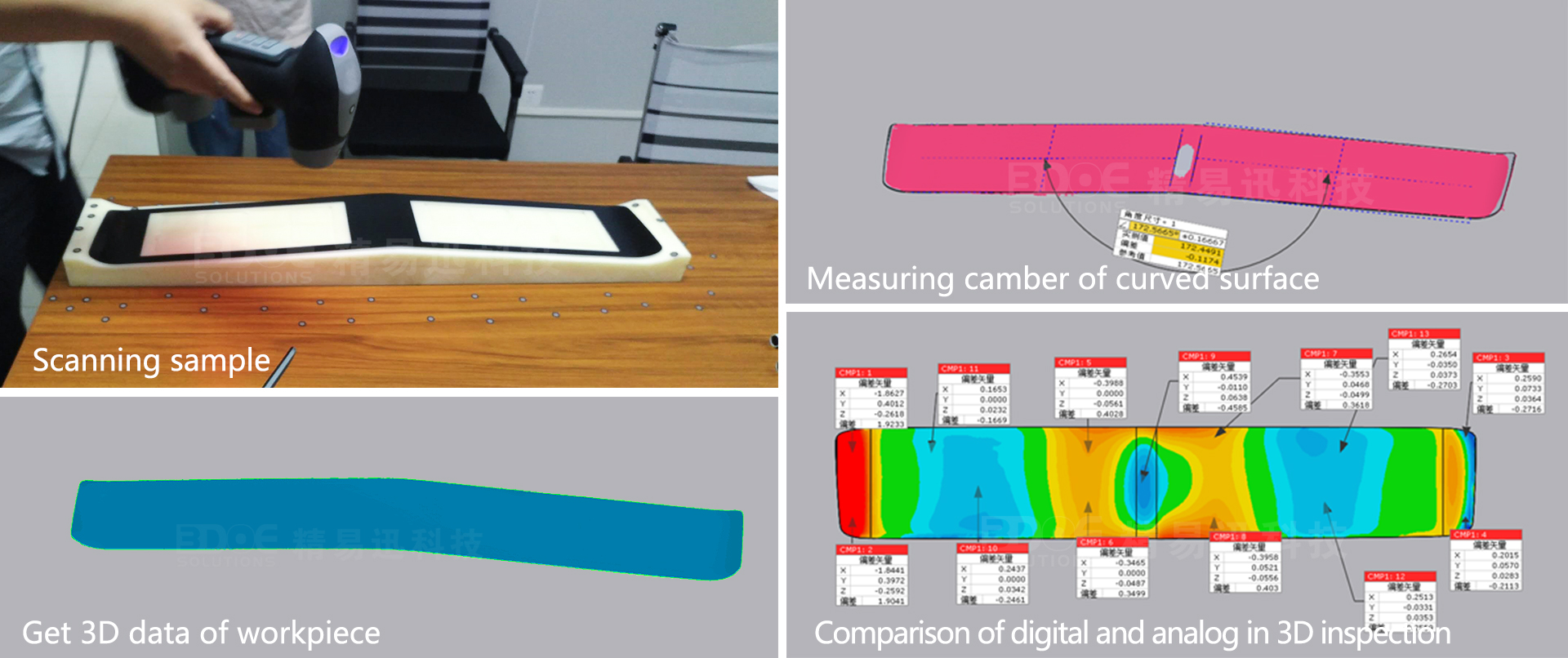

▣ Classic cases

Three-dimensional inspection case of automobile glass

▣ Technical Parameters

Product number | eSharp-P10 | |

Standard mode | Fine mode | |

Measuring speed | 480,000 measurements/sec | 320,000 measurements/sec |

Accuracy (mm) | 0.02 | 0.01 |

Blue laser line | 14 laser lines + 1 deep hole scanning laser line + 5 fine scanning laser lines | |

Laser category | ClassII eye safety level | |

Scanning area(mm) | 275x250 | |

Measuring accuracy(mm) | 0.02 | 0.01 |

Volume accuracy(mm/m) | 0.02+0.06 | —— |

Volume accuracy (mm/m) (Combined with 3D photogrammetry system) | 0.02+0.025 | —— |

Reference distance | 300 | 150 |

Resolution(mm) | 0.04 | 0.02 |

Depth of field(mm) | 250 | 100 |

Data output format | .stl, .obj, .asc, .ply, .txt, .xyz, etc., can be customized. | |

Compatible software | 3D Systems(Geomagic Solutions),InnovMetric Softwre(PolyWorks), Dassault Systems(CATIV V5 and SolidWorks),PTC(PRO/ENGINEER), Autodesk(inventor、Alias、3ds max、Maya、Softimage),Siemens(NX and Solid Edge) | |

▣ Application field

Aerospace: Reverse rapid prototyping, MRO and loss inspection, component and assembly inspection

Automobile industry: styling and design (mud truck), car modification, car interior customization, auto parts quality inspection and measurement

Mold industry: reverse engineering, quality control and size inspection, wear analysis, virtual assembly

New energy: hole assembly, component CAD inspection, robot path programming

To understand the specific application, please feel free to consult online (message) or

call 0755-86131192!

Provide system customized solutions!